Does Natural Gas Have a Role in California’s Carbon Neutral Future?

As California aims to cut emissions to zero by 2045, natural gas use in critical sectors isn’t going away. But the state can reduce its emissions impact by deploying carbon capture and sequestration for efficient, gas-fueled power plants and industrial processes and by mixing low-carbon, “blue” hydrogen and biogas into the pipeline.

The state of California has set the ambitious goal of achieving carbon neutrality by 2045 and by 2018 had already brought statewide greenhouse gas (GHG) emissions 13% below their 2004 peak levels. But despite this success, reducing fossil fuel usage in certain sectors remains a challenge, largely due to the lack of alternatives for high-temperature industrial processes and dispatchable power generation on the grid.

As a result, California will retain a smaller but significant natural gas supply for decades to come.

Nonetheless, it is still possible for California to decarbonize these sectors and achieve its 2045 goal — not by eliminating natural gas entirely, but by deploying carbon capture and sequestration (CCS) in industry and to produce low-carbon hydrogen, and by using a combination of CCS, hydrogen, and biogas to enable on-demand, clean power generation on the grid.

Legislative Efforts Partly Pave the Path Forward to Carbon Neutrality

California has set ambitious zero-emission mandates for sectors with clean alternatives, but its transportation, agricultural, and industrial sectors present their own unique decarbonization challenges.

As shown by recent legislation, California is making significant strides toward reducing fossil fuel usage in the state. Governor Gavin Newsom’s 2020 mandate states that by 2035, all light-duty vehicles sold in California must be zero-emission vehicles. Additionally, California Senate Bill 350 aims to double the state’s energy efficiency over the period from 2015 to 2030, while the state’s Title 24 building code continues to lead the nation in terms of baseline efficiency requirements for new construction. Going further in the push for building electrification, over 40 cities and counties in the state have begun to ban natural gas service in new residential and commercial construction, albeit with important exemptions for hospitals and restaurants.

However, these decisions contrast with the reality that California has added more natural gas customers over the past decade than any other state, highlighting the difficulties of decarbonization even in readily electrified sectors like residential and commercial buildings, where electric heat pumps are close to cost parity with gas heating.

What’s more, current mandates and bans have focused on sectors with readily available clean alternatives, such as renewables on the grid and electrified cars, homes, and buildings, while they have yet to address sectors that have fewer feasible low-carbon options. For instance, the transportation sector will be difficult to entirely decarbonize — after all, medium- and heavy-duty vehicles, aviation, and shipping are noticeably absent from Governor Newsom’s zero-emission vehicles mandate, despite the fact that this portion of the transportation sector accounted for 29% of its emissions in 2018.

Agriculture and industry also present a decarbonization challenge. The agricultural sector’s carbon footprint primarily arises from livestock and land-use practices, which represent their own unique hurdles in the decarbonization effort, while the industrial emissions profile derives directly from using fossil fuels as a feedstock and to produce intense heat. This seems like a ripe challenge for energy experts and technologists around the world, so why haven’t we decarbonized industry as fast as the power sector in recent years?

Industrial Decarbonization Proves a Tough Nut to Crack

Reducing industrial fossil fuel use remains difficult, largely due to the lack of feasible low-carbon technologies that can fuel high-heat processes.

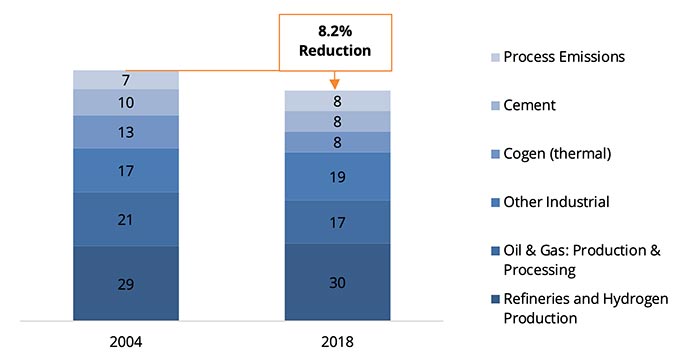

Today, the California Air Resources Board notes that the state’s industrial emissions are “primarily driven” by fuel combustion in refineries, oil and gas extraction, cement plants, and the state’s other prominent manufacturing industries like food and beverage, electronics, and the aerospace industry. The remainder of the state’s industrial emissions arises from greenhouse gases produced by industrial processes and on-site cogeneration systems at industrial facilities.

In this sector, emissions reductions have lagged behind overall emissions cuts. The state’s industrial sector achieved a greater than 8% emissions reduction between 2004 and 2018, with the largest cuts occurring in the oil and gas industry and the state’s existing cogeneration fleet. But at the same time, emissions from refineries, all other industries, and industrial processes ticked up over 6% during that period.

Cutting emissions in the industrial sector has proven to be extremely challenging due to the lack of technologically feasible, low-carbon alternatives for most industrial processes and particularly those that require high-temperature heat. High-temperature heat is crucial to industry because many industrial processes (such as the manufacturing of cement, glass, steel, fertilizer, and paper) require temperatures ranging from 300-1,800 degrees Celsius. That heat also has an outsized impact on the industrial sector’s emissions, accounting for 10% of the entire global economy’s GHG emissions and 13% of the U.S. total. In other words, 58% of total U.S. industrial emissions come from the combustion of fossil fuels to produce high-temperature heat.

Carbon Capture and Sequestration Is the Key to Reducing Industry’s Footprint

Although the industrial sector will need to continue using fossil fuels, it will be able to use blue hydrogen and Carbon Capture and Sequestration (CCS) to zero out its emissions.

A 2019 study from Columbia University’s Center on Global Energy Policy (CGEP) surveys all possible options for low-carbon heating in heavy industry and concludes with two clear winners: blue hydrogen and CCS. Blue hydrogen is produced via the regular hydrogen manufacturing process, which involves steam methane reforming of a natural gas feedstock, but utilizes CCS to capture up to 89% of the resulting emissions. As the study notes, blue hydrogen is at least 3 times more cost-effective than green hydrogen, which uses renewable energy for hydrogen production via electrolysis.

For certain industrial sites and power plants that rely on fossil fuels, substituting those fuels with blue hydrogen could allow them to continue their operations without interruption, while simultaneously zeroing out their GHG footprint. A single major CCS retrofit at a central hydrogen manufacturing facility would be a cost-effective way to provide blue hydrogen to many industrial sites and power stations at once.

However, industrial facilities have highly engineered processes and equipment, and due to fuel compatibility issues, not every site will be able to utilize hydrogen or electric heat in place of natural gas, coal, or oil. For instance, steel and cement production cannot currently use substitute fuels. In other cases, the costs of reengineering highly integrated equipment to use hydrogen or electricity would be prohibitive, especially as most equipment is expected to last upwards of 80 years. In these cases, most sites would be able to retrofit their facilities with CCS without changing their underlying manufacturing processes, which is pricey but not necessarily prohibitive if reducing emissions is a key goal.

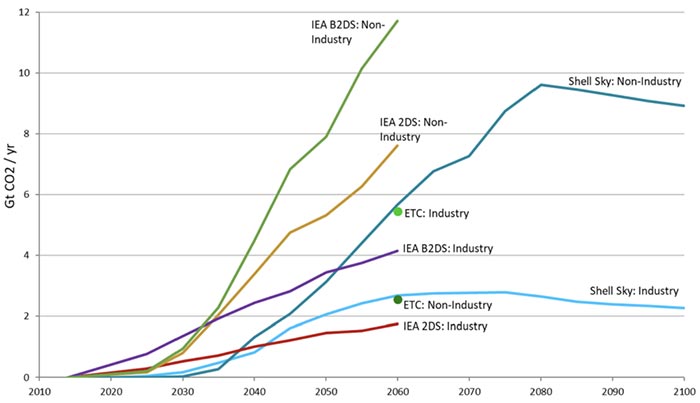

Beyond Columbia University’s study, other long-term forecasts agree that CCS will be critical for the industrial sector to achieve a zero-carbon future. Shell, the Energy Transitions Commission, and the International Energy Agency’s 2-Degree Scenario (IEA 2DS) expect the global industry to capture 2-4 billion tons of CO₂ annually by 2060, equivalent to 30-65% of 2018 worldwide industrial CO₂ emissions.

Annual Global CO₂ Capture Rate

Dispatchable, Clean Power Underpins a Carbon Neutral Grid

While the power sector has steadily decarbonized in recent years, California has a long way to go, and the state will run into intermittency and other logistical problems as it expands renewables and attempts to reduce fossil fuel use on the grid.

Renewable technologies like solar and wind are a natural substitute for fossil fuel generators on the grid, but a 100% renewable energy mix isn’t the most likely outcome in California’s carbon-neutral future, largely due to intermittency issues, as well as economic and political limitations.

Solar and wind are intermittent or variable power producers, and as their prevalence grows, California’s grid will need more dispatchable, clean power generation and energy storage to counteract this intermittency. Reliability is already a major concern on the California grid, especially with utilities implementing Public Safety Power Shutoffs (PSPS) during periods of elevated fire risk since 2019. At the same time, Governor Newsom’s zero-emission vehicle mandate is expected to increase the state’s electricity demand by 9–25% by 2035, which, along with increased heating electrification in buildings and homes, will only compound the state’s power reliability problems.

Another headwind for the growth of renewable generation in the state is the well-documented fact that solar’s value drops by over two-thirds when it generates one-third of a region’s electricity. At the same time, the need for open swathes of land will surely impede further renewables growth in the state, exemplified by the fact that the growth of wind power in California has stagnated since 2012 due to siting constraints and bans on large-scale wind development in several of the state’s largest counties.

For these reasons, California needs to retain a mix of resources on the grid, with a focus on dispatchable generation technologies with few roadblocks to widespread implementation. Unfortunately, some options remain out of reach due to public opinion (as seen with large-scale nuclear), while others represent insurmountable geographical and siting issues (as seen with geothermal and hydropower), or offer only short-term relief, like lithium-ion batteries which suffer from short discharge durations.

Carbon Capture Is the Lynchpin for a Clean California Grid

By using carbon capture and sequestration for natural gas power plants, California can cut emissions while still ensuring that power is reliable and resilient.

From today’s arsenal of commercially available, clean, and dispatchable technologies, CCS-equipped natural gas generation is the most likely resource to make a big impact on the California grid. Natural gas power plants are highly dispatchable, so they can uphold a reliable grid, and they produce cost-effective energy. And while they already burn a cleaner fossil fuel than oil or coal, natural gas power plants can implement CCS to reduce their emissions to zero. Additionally, gas-fueled power generation already plays an outsized role in the state and these plants could be retrofitted with CCS in the coming decades at lower costs than building brand new power stations. This is a proven solution, as there are currently 19 large-scale CCS facilities operating globally at a mix of industrial sites and power stations, and another 32 in development, including two CCS-equipped power plants in California, planned to begin operation in the mid-2020s.

Power plants can further reduce carbon intensity on the front end of power generation by mixing biogas and small amounts of hydrogen into the natural gas pipeline. The utility of hydrogen is limited, due to the poor hydrogen compatibility of gas turbines. But a power plant that uses biogas and carbon capture may actually achieve net-negative emissions by sequestering carbon from this partially renewable fuel.

This pathway is also expected to be a cost-effective solution in the decades to come. A research review from MIT confirms that a mix of technologies that includes natural gas CCS and bioenergy could potentially reduce electricity costs 10-62% compared to a 100% renewable grid, while still achieving carbon neutrality. Although a slew of next-generation technologies, including long-duration energy storage and advanced nuclear reactors, are also being developed to balance the 100% clean power grids of the future, these options are at least a decade or two away from making a meaningful contribution. Given this energy landscape, CCS will surely play an important role on a carbon-neutral grid.

California’s Path to Decarbonization Includes Natural Gas

California can fully decarbonize its economy by 2045. However, this does not mean it can fully wean its industries off natural gas by that date, as certain sectors, including industry and transportation, do not have feasible alternative technologies available. What’s more, natural gas ensures power grid reliability, especially as the proportion of renewable energy resources increases. It’s highly likely that natural gas will play a role in California’s power mix for decades to come — but that doesn’t mean the state’s carbon-neutral goal is out of reach. California must ensure that hard-to-decarbonize sectors can deploy CCS, and mix biogas and hydrogen into the natural gas supply, in order to reduce emissions while ensuring vital industries remain operational and competitive.

For more insight into how Unison Energy’s solutions can cut emissions at your facility, click here to contact Unison Energy.

Energy insights, delivered

Subscribe for more content.

Related Blogs

The Texas Infrastructure Resiliency Fund: Empowering Businesses with Onsite Microgrids

Deadlines for the Inflation Reduction Act

Canadian Carbon Reduction Incentives: What You Should Know