Safety Protocols During Construction

Unison Energy culture includes safety as part of the fabric of our daily jobs. During construction, installation, and commissioning, this necessarily includes not only our own team but our contractors as well.

Unison Energy fosters a “Safety First, Safety Always” culture throughout construction, installation, and commissioning. That standard applies to the third-party construction firms we hire to perform civil, structural, mechanical, and electrical construction and installation services. We are committed to ensuring that our contractors adhere to industry best practices and trendsetting safety standards, incorporating both our clients’ and Unison Energy’s safety policies. We select contractors that meet our rigorous standards, then develop a comprehensive safety culture specific to each site, continually working to ensure key performance indicators (KPIs) are met and sites remain in compliance.

Start With Internal Standards

From individual technicians to the highest level of leadership, we expect Unison Energy team members to actively foster a safety culture. Our Safety Committee, which reports to the Board of Directors and is chaired by our Co-CEO, brings together operations and executive leadership with our operations and maintenance team for a comprehensive top-down/bottom-up approach. This committee is responsible for creating, implementing, overseeing, and reporting on Unison Energy’s safety policies, procedures, and practices. When we look for contractors, we require them to be aligned with supporting our safety ethos.

Choose Contractors that Prioritize Safety

We review contractors’ public OSHA recordable incidents, looking for Experience Modification Rates (EMR) furthest below 1 (the national average). EMR measures past-claim costs and is used to calculate compensation premiums such that safer companies pay less.

Our selection process includes a pre-bid walkthrough to discuss the importance of safety and their performance on comparable past projects. Contractor proposals are expected to include a range of key safety data and an inclusive and thorough corporate safety policy.

Develop a Site-Specific Safety Culture

Prior to mobilization, we develop and post a site-specific safety response plan that includes safety management and superintendent contact information, as well as evacuation routes and emergency procedures. Required job signage includes project-specific PPE requirements, check-in and check-out requirements, and warning signage.

At mandatory safety orientations, all workers learn relevant project protocols, including specific Unison Energy, contractor, and facility requirements. Contractors must hold daily 15- to 30-minute “tailgate” meetings to discuss topics relevant to the work at hand, such as working at heights or using correct PPE. This job hazard analysis ensures workers are cognizant of hazards before they start.

Most importantly, we recognize that safety is a product of both established standards and continuous improvement. Our team actively seeks out contractor suggestions based on previous experience or site observations on how to improve safety.

Enforce Compliance With Site Safety Protocols

Supervision, reviews, and documentation help us ensure that safety protocols are being satisfactorily implemented. Workers must “sign off” on orientations and contractors need safety oversight staff in place. We also walk through sites at least weekly, checking that PPE is in use, sites are clean and marked properly, and equipment is inspected. Tracking data offers critical safety insights and allows us to be proactive about making changes as needed. Contractors report on performance and safety KPIs, which include our preferred KPIs as well as their own. For instance, we commercially obligate that they include total man-hours worked on-site, and any first aid, near miss, recordable, and lost time incidents.

Our Ongoing Safety Improvement

We often think of safety performance in terms of leading and lagging indicators. Lagging indicators are about past performance, to see if our strategies worked as intended — like looking in a rearview mirror. With leading indicators, we look ahead, down the road, to understand which of today’s performance metrics are most useful for ensuring the safety of future projects. We continue to learn from each experience, track key indicators, and develop industry-leading safety protocols.

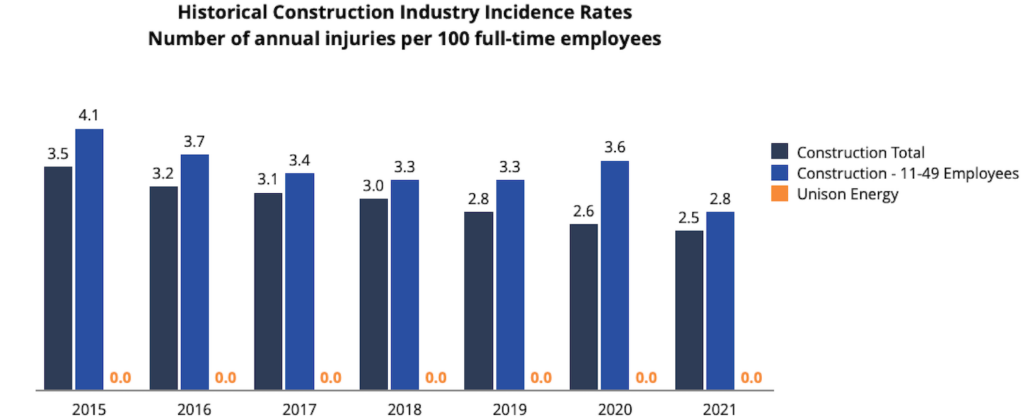

Historical Construction Industry Incidence Rates

Kirk Arneson – Director of Project Management

Energy insights, delivered

Subscribe for more content.